Loading...

A 2% efficiency gain in logistics doesn't sound impressive until you realize it's worth millions.

This industry runs on margins so thin you can see through them. Fuel costs, labor, warehousing, last-mile delivery. Every wasted mile, every misrouted package, every poorly stocked shelf erodes what little profit exists. Small improvements compound into massive financial impact.

AI optimization across the supply chain cuts costs by 15-25% while actually improving delivery reliability. Not by working people harder. By working smarter at every link in the chain.

Route Optimization That Thinks in Real Time

Traditional route planning is a snapshot. Plan the routes in the morning. Send the drivers out. Hope traffic cooperates. Hope the delivery windows don't conflict. Hope the truck capacity calculations were right.

AI route optimization is a living system. It doesn't just plan routes. It continuously recalculates them.

The AI considers dozens of variables simultaneously. Current traffic conditions, not yesterday's averages. Each delivery's time window. Vehicle capacity and weight limits. Fuel consumption patterns for each vehicle type. Driver hours and mandatory break schedules. Road restrictions. Weather conditions. Even the probability of a customer not being home based on historical patterns.

When a highway shuts down at 2 PM, the system reroutes affected vehicles in minutes. When a delivery gets cancelled, the remaining stops get resequenced to save fuel and time. When a priority order comes in, it gets slotted into the most efficient position across the entire fleet.

One logistics company we've studied saved 18% on fuel costs in the first quarter after implementing AI routing. Not because the old routes were terrible. Because the AI found thousands of small optimizations that no human planner could process simultaneously.

Demand Forecasting That Prevents Both Waste and Stockouts

Inventory is a bet. Stock too much and you're paying for warehouse space, insurance, and eventual write-offs on expired or obsolete goods. Stock too little and you're losing sales, disappointing customers, and scrambling for emergency shipments that eat margins alive.

Traditional forecasting uses historical averages, seasonal adjustments, and a lot of gut feel. It works okay for stable products in predictable markets. It fails spectacularly when things change. A TikTok trend makes your product go viral. A competitor launches a substitute. A raw material shortage disrupts supply. A heatwave changes buying patterns.

AI forecasting models absorb a much wider range of signals. Historical sales data, obviously. But also weather forecasts. Social media sentiment. Economic indicators. Competitor pricing changes. Promotional calendars. Local events that affect demand. Even news articles about related industries.

The result is demand predictions accurate enough to run lean inventory without the constant terror of stockouts. Safety stock drops 20-30% while fill rates actually improve. That's freed capital, reduced waste, and happier customers all at once.

For perishable goods, the impact is even more dramatic. Better demand forecasting means less food thrown away. Less medicine expired. Less product manufactured only to sit on a shelf and depreciate.

Warehouse Operations That Run Like Clockwork

Walk into a traditional warehouse and watch a picker's path. It looks random. Zigzagging across aisles. Backtracking. Walking past items they'll need in ten minutes. The pick path is often 2-3x longer than it needs to be because nobody optimized the layout for the current order mix.

AI warehouse management reimagines every aspect of the operation.

Storage location optimization places frequently ordered items near packing stations. Items commonly ordered together get positioned in adjacent slots. Seasonal products rotate to accessible locations before demand spikes, not after.

Pick path optimization sequences orders so the picker moves through the warehouse in one clean sweep. No backtracking. No wasted steps. AI batches orders intelligently so one trip fills multiple shipments.

Staffing predictions match labor to actual workload. Monday morning rush needs more pickers. Tuesday afternoon lull needs fewer. Instead of overstaffing for peaks and carrying idle labor during valleys, AI staffing models put the right number of people in the right places at the right times.

Smart warehouses running AI management see 20-30% throughput improvements. Labor costs drop 15-20%. And the warehouse doesn't even look faster from the outside. It just flows. No bottlenecks. No chaos. No pile-ups at the packing stations.

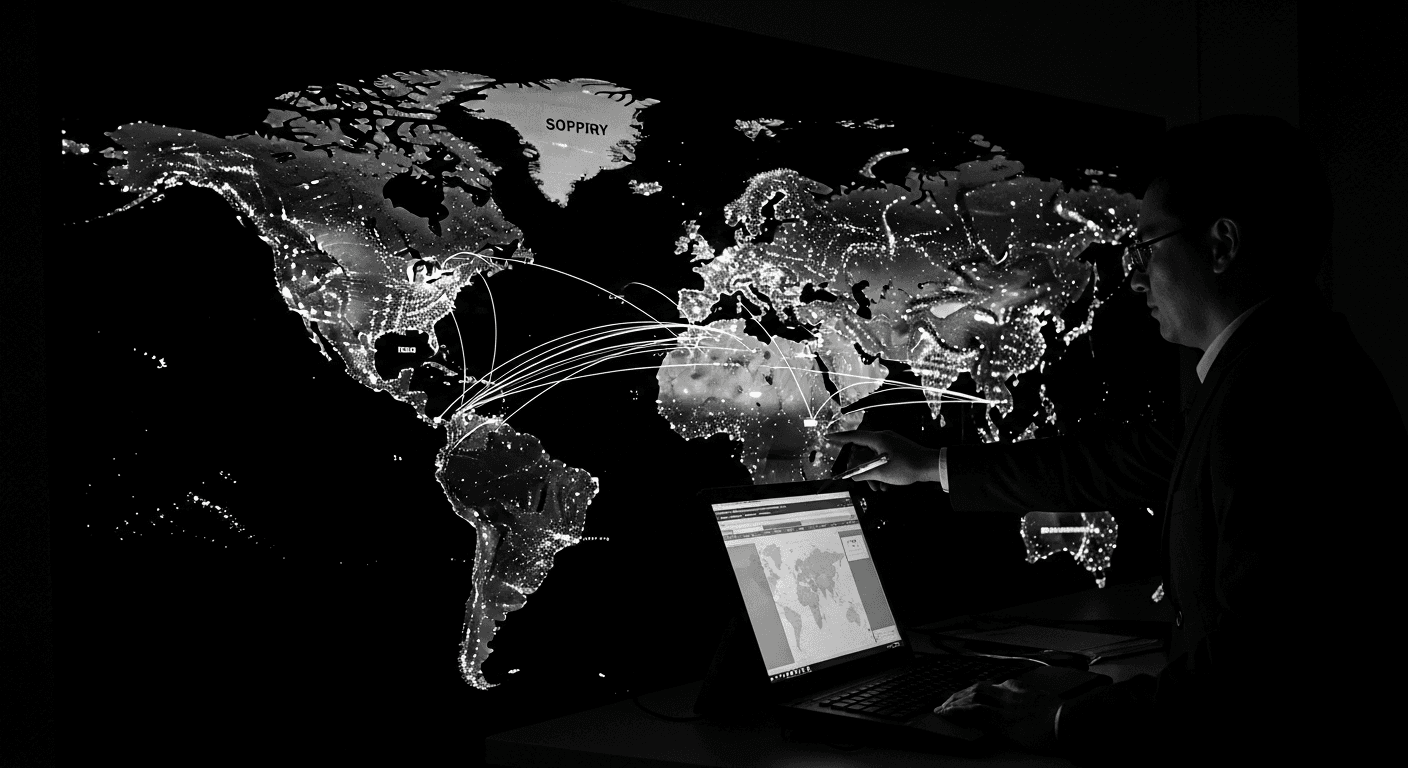

End-to-End Visibility

The biggest win might be the simplest one. Knowing where everything is. In real time. Across every supplier, warehouse, truck, and delivery point in your network.

AI-powered supply chain visibility connects the dots that traditionally lived in separate systems. A delay at a port triggers automatic alerts to affected warehouses. A production slowdown at a supplier triggers procurement of alternative sources before stock runs out. A weather system approaching a distribution hub triggers preemptive rerouting of inbound shipments.

No surprises. No fire drills. Just calm, data-driven responses to a world that never stops throwing curveballs at your supply chain.

The logistics companies that win in the next decade won't be the biggest. They'll be the most responsive. AI gives a mid-size operator the optimization capability that used to require an army of analysts.

Related Articles

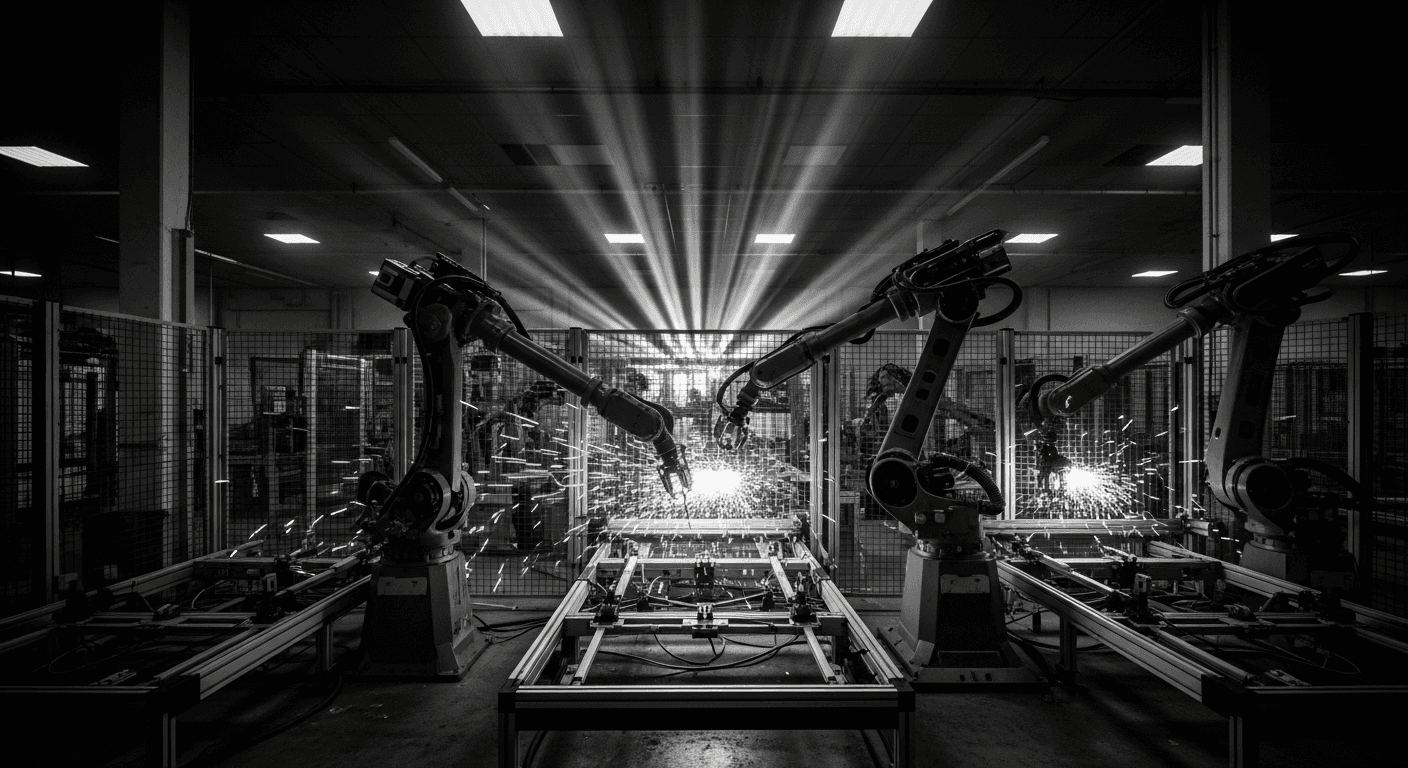

AI in Manufacturing: Building Smart Factories

Manufacturers deploy AI agents for predictive maintenance, quality control, supply chain optimization, and production planning.

AI in E-Commerce: Retail Intelligence and Personalization

E-commerce businesses use AI for product recommendations, inventory optimization, pricing strategy, and personalized shopping experiences.

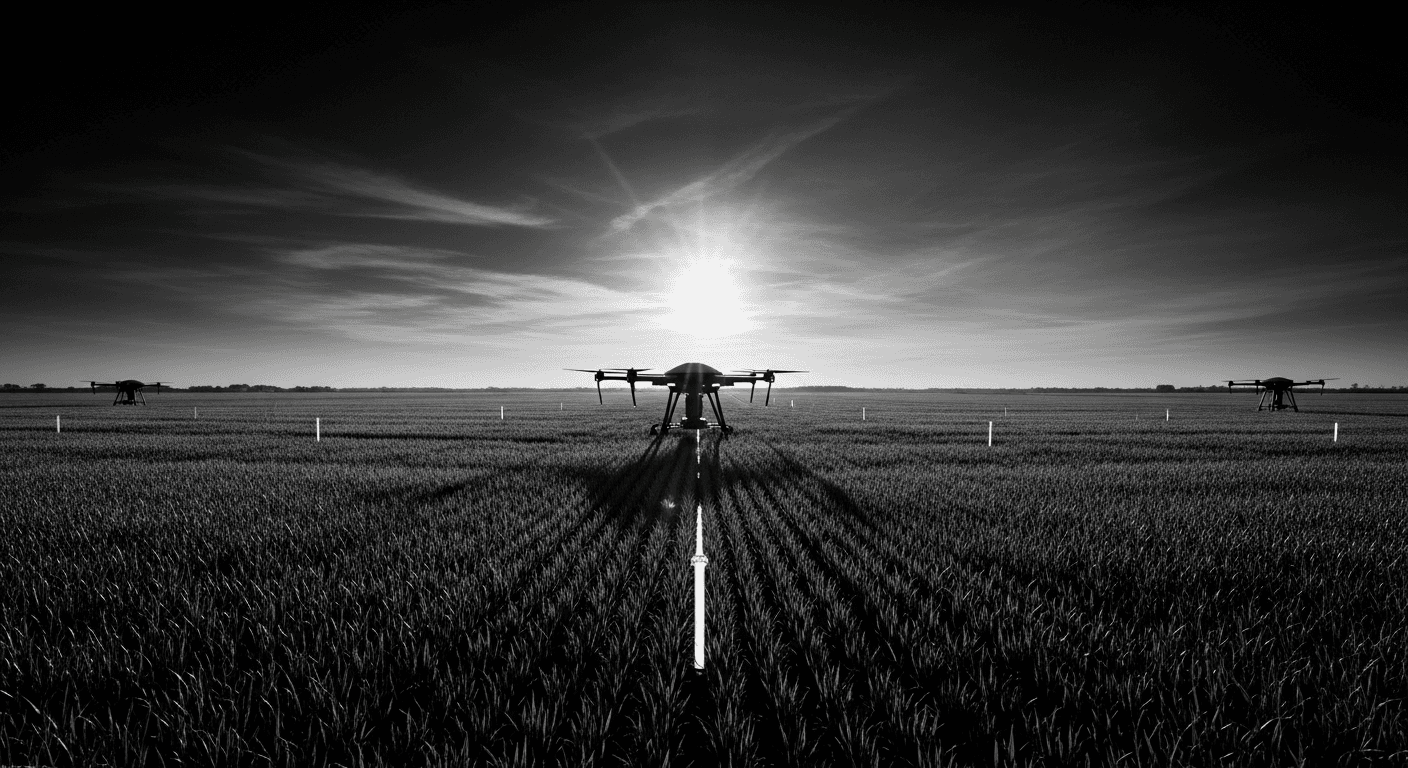

AI in Agriculture: Precision Farming and Crop Intelligence

Agricultural operations use AI for crop monitoring, yield prediction, resource optimization, and sustainable farming practices.

Want to Implement This?

Stop reading about AI and start building with it. Book a free discovery call and see how AI agents can accelerate your business.