Loading...

Construction has a reputation problem. And it's earned.

The average large construction project finishes 20% over budget and 80% past its original deadline. Those aren't outlier numbers. That's the industry average. Two decades of project management software haven't moved the needle because the fundamental problem isn't tracking. It's prediction.

AI brings data-driven prediction to an industry that has run on gut instinct and optimistic estimates since the pyramids.

Scheduling That Accounts for Reality

A project manager building a schedule does their best. They estimate durations based on experience. They map dependencies. They build in some buffer. They present a timeline to the client.

Then reality happens. Concrete delivery is delayed by two days. The electrical subcontractor is stretched thin across three other projects. An unexpected soil condition requires additional foundation work. Rain washes out a week of exterior work.

Traditional schedules break on contact with reality because they're built on averages and assumptions. AI scheduling is built on data and probabilities.

AI scheduling models analyze thousands of completed projects to understand how long tasks actually take. Not how long they're supposed to take. How long they take in practice, given variables like weather, crew size, material availability, and project complexity.

Dependency analysis goes deeper than "Task B starts after Task A." AI identifies soft dependencies that human planners miss. A delay in HVAC rough-in doesn't just delay HVAC. It delays insulation, which delays drywall, which delays paint, which pushes the entire interior finish timeline. AI traces these cascading impacts instantly.

Weather integration incorporates historical weather data and forecasts into the schedule. Instead of hoping for good weather during the concrete pour, the AI identifies windows with the highest probability of suitable conditions and schedules accordingly.

The result isn't a perfect schedule. No schedule survives perfectly. But AI schedules are 30-40% more accurate in duration prediction than human estimates. And when disruptions happen, the AI recalculates the entire project impact in minutes, not days.

Cost Estimation That Builders Can Trust

"How much will this cost?" The most important question in construction. And the most poorly answered.

Manual cost estimation involves an experienced estimator reviewing drawings, counting quantities, applying unit costs, adding markup, and presenting a number. The process takes weeks and the result is typically within 15-30% of actual costs. On a $10 million project, that's a $1.5-3 million swing. Nobody should be making financial commitments with that kind of uncertainty.

AI cost estimation delivers consistently better accuracy. 5-10% variance from actual costs.

Here's how. The AI analyzes historical cost data from thousands of completed projects, adjusted for current material prices, local labor rates, and project-specific conditions. It identifies cost patterns that human estimators miss. Projects of this type, in this region, at this time of year, with this complexity level, cost this much.

Quantity takeoffs from digital plans happen in hours instead of days. The AI reads architectural and structural drawings, counts elements, calculates areas and volumes, and applies current pricing. A process that used to take an experienced estimator a week happens overnight.

Change order impact analysis runs in real time. The client wants to add a floor? The AI calculates not just the direct cost of additional materials and labor, but the schedule impact, the crane time implications, the effect on foundation loading, and the permit requirements. A comprehensive change order response in hours instead of weeks.

Safety Monitoring That Prevents Incidents

Construction is one of the most dangerous industries in the world. Falls, struck-by incidents, electrocution, and caught-between hazards kill hundreds of workers every year. Thousands more are injured. Traditional safety monitoring relies on periodic inspections and hoping people follow the rules when nobody's watching.

AI safety monitoring watches constantly.

Computer vision systems analyze feeds from site cameras and identify safety violations in real time. A worker without a hard hat in a hard hat zone triggers an immediate alert. An unsecured scaffolding bracket gets flagged. A vehicle entering a pedestrian zone gets caught.

These aren't after-the-fact reports. They're real-time warnings. The site safety manager gets a notification on their phone within seconds of a violation. Not at the end of the day. Not during the next safety walk. Right now. While there's still time to prevent an injury.

Predictive safety analysis goes further. By analyzing patterns of near-misses, safety observations, weather conditions, and work activities, AI identifies when and where incidents are most likely to occur. High-risk periods get additional safety resources. High-risk areas get temporary barriers or restricted access.

One general contractor reported a 45% reduction in recordable incidents after implementing AI safety monitoring. Not through stricter rules. Through faster detection and proactive prevention.

Quality Inspection at Scale

Punch lists at the end of a construction project are a nightmare. Hundreds of items to inspect. Defects to document. Remediation to track. The process takes weeks and always seems to find more issues.

AI quality inspection catches defects during construction, not after. Computer vision analyzes progress photos and identifies workmanship issues in real time. A wall that isn't plumb. Tile spacing that's inconsistent. Paint coverage that's uneven.

Catching these issues during construction is 5-10x cheaper than fixing them during punch-out. The work gets redone while the crew is still on site, the materials are still available, and the area is still accessible.

Construction isn't going to transform overnight. It's a conservative industry with deep habits. But the projects using AI are finishing closer to budget, closer to schedule, and with fewer injuries. That's not a technology argument. It's a results argument. And results are hard to ignore.

Related Articles

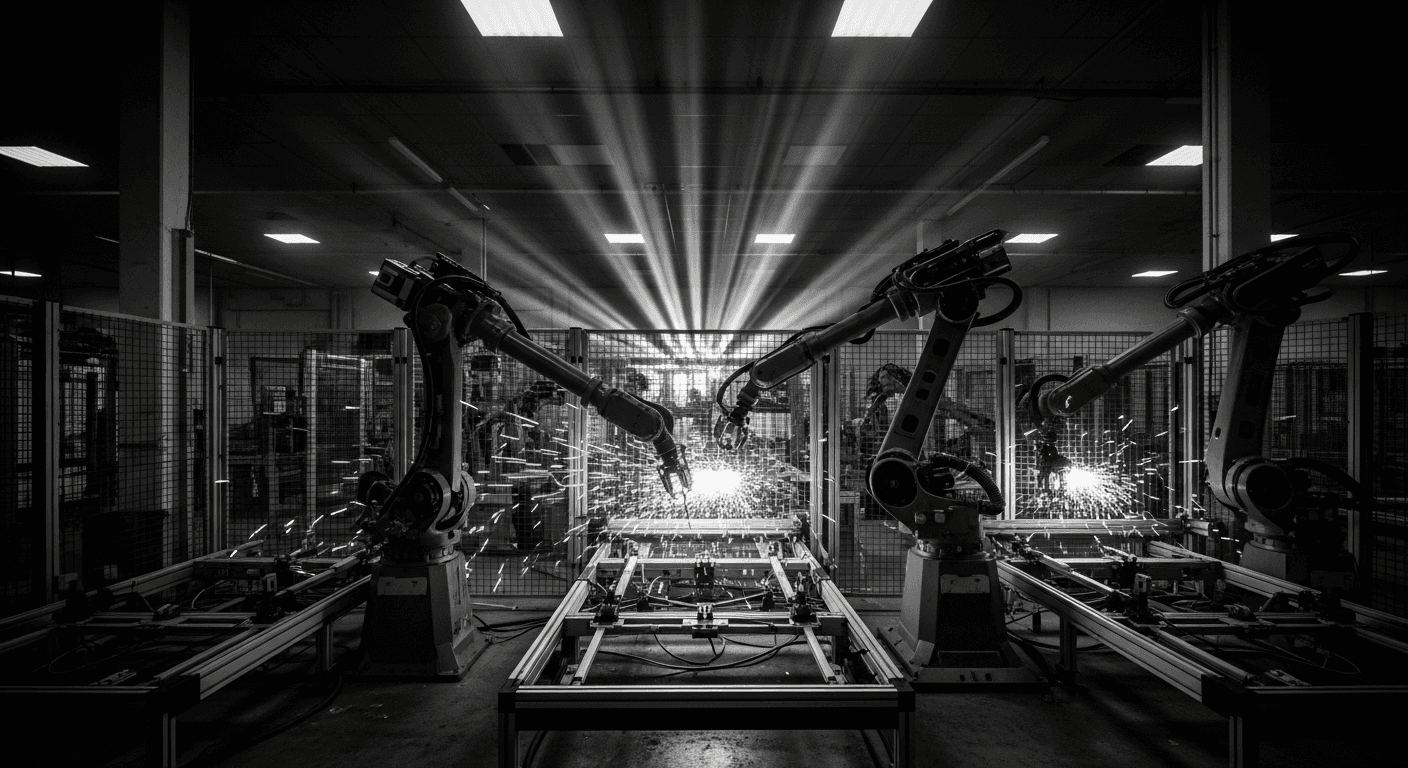

AI in Manufacturing: Building Smart Factories

Manufacturers deploy AI agents for predictive maintenance, quality control, supply chain optimization, and production planning.

AI in Real Estate: From Property Search to Transaction Close

Real estate professionals use AI agents to value properties, generate listings, qualify buyers, and streamline the entire transaction process.

AI in Agriculture: Precision Farming and Crop Intelligence

Agricultural operations use AI for crop monitoring, yield prediction, resource optimization, and sustainable farming practices.

Want to Implement This?

Stop reading about AI and start building with it. Book a free discovery call and see how AI agents can accelerate your business.